Our transparent and collaborative process guarantees that your project is delivered exactly as agreed

How we work

When you work with us, you work with a team of professionals who follow a detailed process that incorporates a collaborative communication and feedback approach, with robust safety protocols. Our proven process ensures your project is delivered on schedule, to specification and to budget, every time.

Our team members coordinate closely with each other to create joinery, metalwork, solid surfaces or upholstery elements using:

- best practice project management

- precise manufacturing processes

- safe delivery in our own vehicles

- careful installation

- quality control checks

- defects rectification if required.

The process

01 Provide detailed scope of works and costings

02Create a schedule of works programme

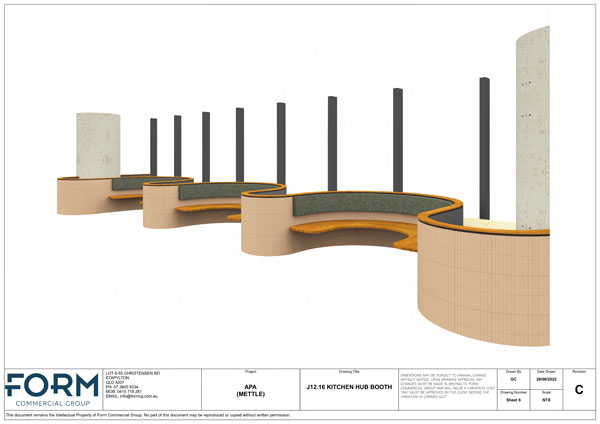

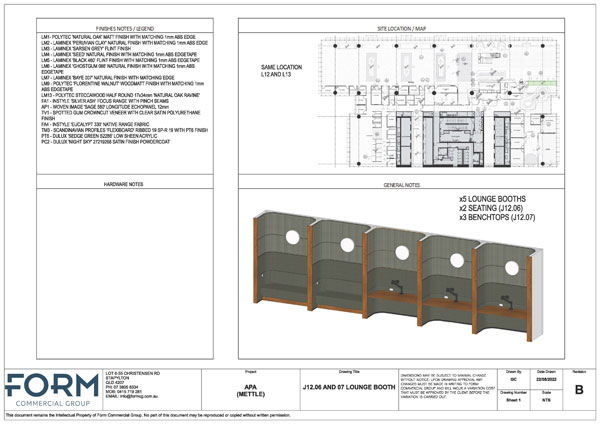

03 Take the plans, elevations, sectional view, finishes and fixtures schedule, and create detailed 2D and 3D shop drawings using photo realistic finishes and colours. This ensures you can see what the finished products will look like and how they sit within their surroundings

04 Submit all documentation and drawings to you for review and feedback, amending as required until client is 100% happy with them

05Procure all required materials

06 Process the shop drawings into our CNC router equipment, proceed with machining ready for manufacture

07 Manufacture all components in factory with all steps monitored and quality checked

08 Label each item and component to assist with manufacture tracking and installation.

09 Deliver all items to sites using Form Commercial Group vehicles.

10 Installation of all components and prepare the space for clients’ review

11 Project hand over with client, schedule maintenance when required